TS EN / DIN Tiùb stàilinn gun ròin Galvanized Àrd-chinnt

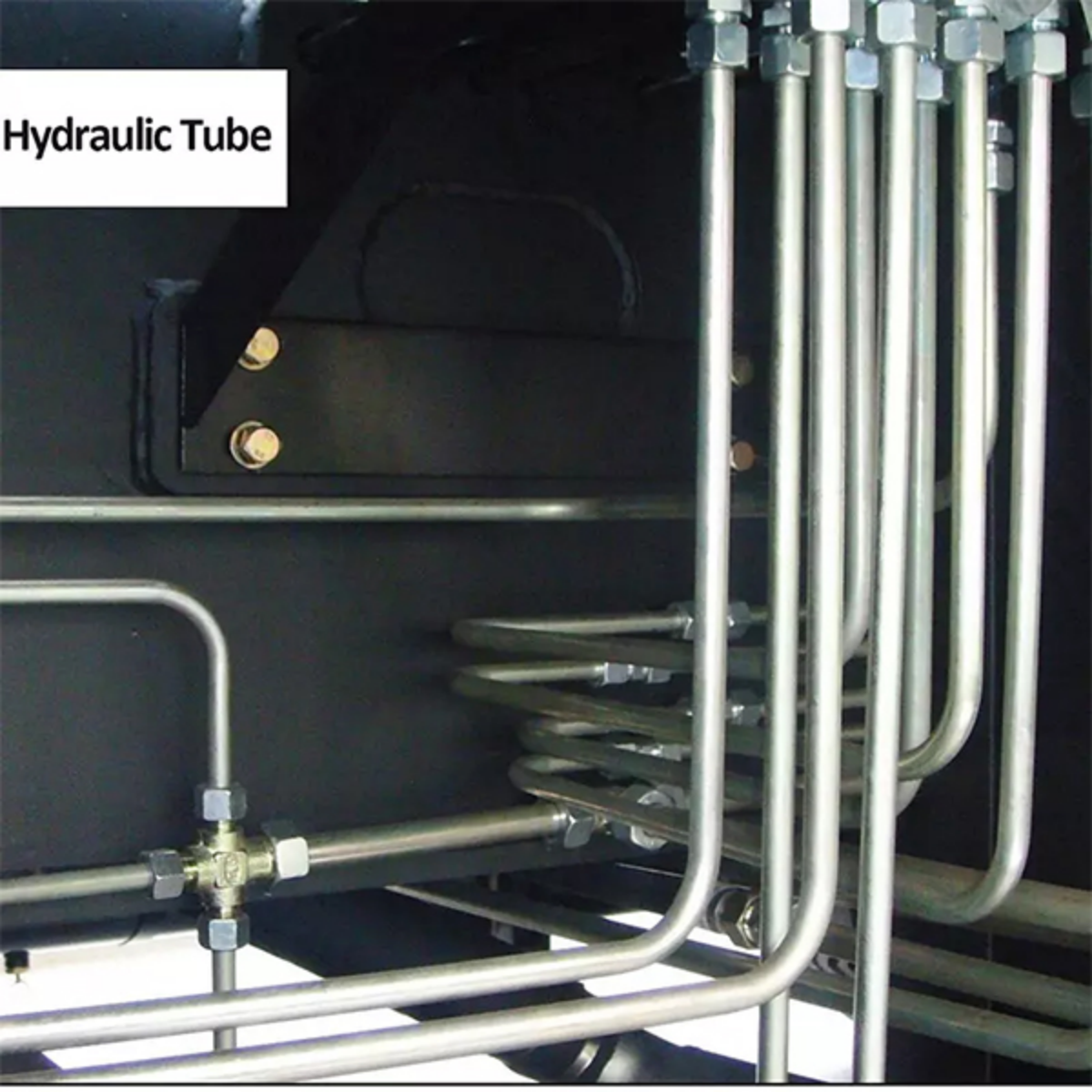

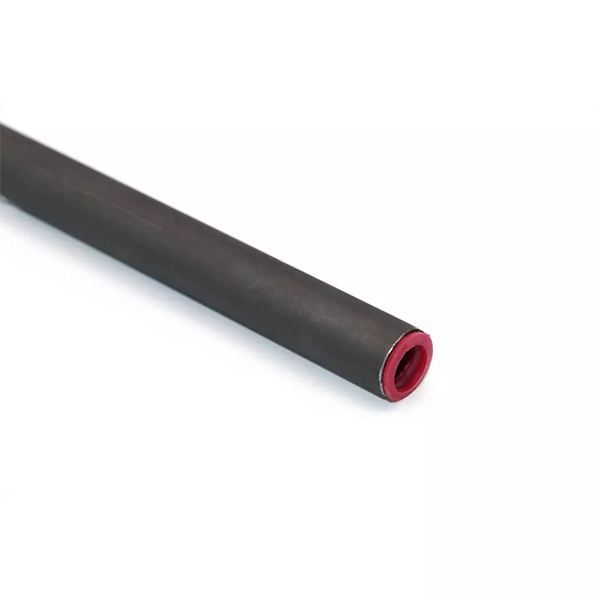

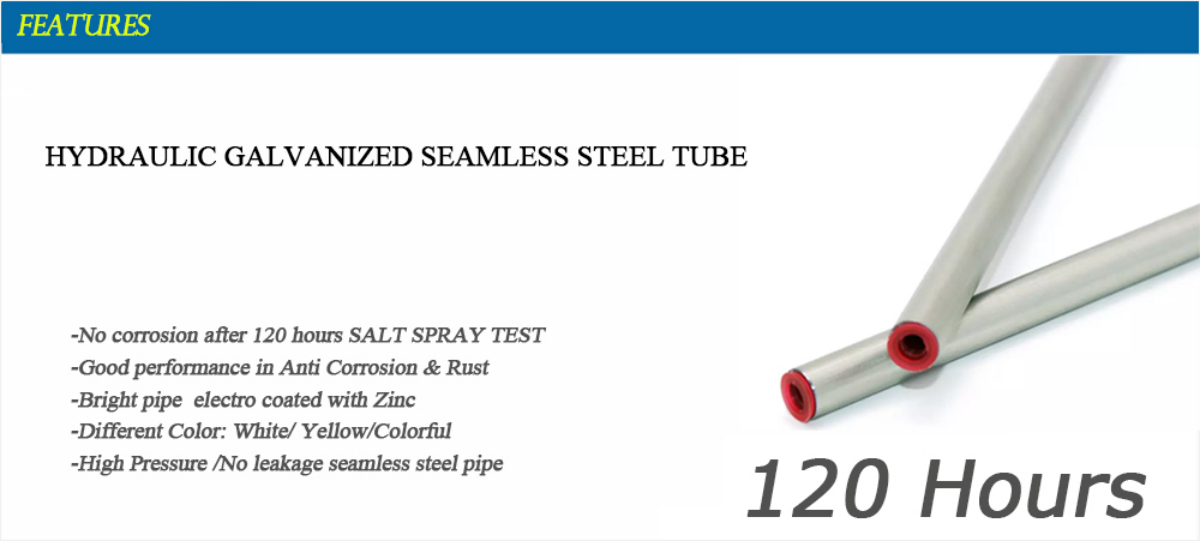

Tha Tiùb Stàilinn Galvanized Àrd-chruinneas EN / DIN air a thoirt a-mach stèidhichte air DIN 2391-C agus EN10305-4.Tha e air a chleachdadh gu farsaing ann an siostaman uisgeach, innealan inneal, càraichean, soithichean, innealan togail agus carbadan.Tha mòran bhuannachdan aig a’ phìob stàilinn fuaigheil ghalbhanaichte Hydraulic le mionaideachd àrd: Gun choire às deidh 120 uair SALT SPRAY TEST;Coileanadh math ann an Anti Corrosion & Rust;Dealan pìoba soilleir còmhdaichte le sinc;Dathan eadar-dhealaichte: Geal/Buidhe/Dathte;Bruthadh Àrd / Gun aoidionachd pìob stàilinn fuaigheil.

Sònrachadh

| Inbhe | DIN2391 DIN1630 EN10305 DIN2445 JIS G3445 SAE J524 |

| Ìre | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Suidheachadh lìbhrigidh | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Meud | OD: 4 gu 219mm Tighead 0.5-35mm, Fad: 3m,5.8,6 no a rèir riatanasan |

| Crìochnaich | Uachdar galvanized (Sliver / Buidhe / Dathach) Còmhdach sinc de 8-12um |

| Iarrtas | Siostam Hydraulic;Càr/bus;carbad togail |

| Ùine lìbhrigidh | A.3 làithean ma tha seo math tha stoc bathair.B. Mu 30 latha a rèir meud |

| Tube STEEL PRECSION HYDRAULIC ANN AN stoc | ||||||||||

| OD | Tighead(mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Nota: Dh'fhaodadh sinn meudan eile a thoirt gu buil mar na riatanasan agad.Làimhseachadh uachdar: Bright, Galvanized, Phosphating etc. | ||||||||||

Co-dhèanamh ceimigeach

| Ìre stàilinn | C | Si | Mn | P | S | Al | |

| Ainm | Chan eil. | max | max | max | max | max | max |

| E215 | 1.0212 | 0.1 | 0.05 | 0.7 | 0.025 | 0.015 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.025 | 0.015 | - |

| E355 | 1.058 | 0.22 | 0.55 | 1.6 | 0.025 | 0.015 | - |

| ST35 | 1.0308 | 0.17 | 0.35 | 0.4 (mion) | 0.025 | 0.025 | - |

| ST45 | 1.0408 | 0.21 | 0.35 | 0.4 (mion) | 0.025 | 0.025 | - |

| ST52 | 1.058 | 0.22 | 0.55 | 1.6 | 0.025 | 0.025 | - |

Feartan meacanaigeach

| Ìre stàilinn | Neart toraidh (Mpa) | Neart tensile (Mpa) | Leudachadh (%) | |

| Ainm | Chan eil. | ReH (mion) | Rm(mion) | A(mion) |

| E215 | 1.0212 | 215 | Bho 290 gu 430 | 30 |

| E235 | 1.0308 | 235 | Bho 340 gu 480 | 25 |

| E355 | 1.058 | 355 | Bho 490 gu 630 | 22 |

| ST35 | 1.0308 | 235 | Bho 340 gu 480 | 25 |

| ST45 | 1.0408 | 255 | Bho 440 gu 570 | 21 |

| ST52 | 1.058 | 355 | Bho 490 gu 630 | 22 |

Fulangas

| OD | Fulangas ceadaichte | Fulangas sònraichte | ||

| GB/T3639 | DIN2391 | OD | WT | |

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm |

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm |

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm |

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm |

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm |

Suidheachadh lìbhrigidh

| Ainmeachadh | samhladh | Tuairisgeul |

| Crìochnaichte fuar (cruaidh) | BK(+C) | Cha bhith pìoban a’ faighinn làimhseachadh teas às deidh an fuachd mu dheireadh a chruthachadh agus, mar sin, tha iad gu math àrd an aghaidh deformachadh |

| Crìochnaichte fuar (bog) | BKW | Tha an làimhseachadh teas mu dheireadh air a leantainn le dealbh fuar le beagan deformachadh.Tha tuilleadh giollachd iomchaidh a’ ceadachadh ìre sònraichte de fhuarachadh (me lùbadh, leudachadh) |

| (+LC) | ||

| Crìochnaichte fuar agus faochadh cuideam | BKS(+SR) | Tha làimhseachadh teas air a chuir an sàs às deidh a ’phròiseas cruthachadh fuachd mu dheireadh.Le ùmhlachd do chumhachan giullachd iomchaidh, tha an àrdachadh anns na cuideaman a tha air fhàgail a ’comasachadh an dà chuid cruthachadh agus innealachadh gu ìre. |

| Annealed | GBK(+A) | Tha am pròiseas cruthachaidh fuachd mu dheireadh air a leantainn le bhith a’ annealing ann an àile fo smachd. |

| Normalaichte | NBK(+N) | Tha am pròiseas cruthachaidh fuar mu dheireadh air a leantainn le bhith a’ cur anail os cionn na h-ìre cruth-atharrachaidh àrd ann an àile fo smachd. |

Dearbhadh càileachd

1.Strict a rèir DIN2391 / EN10305 no inbhean eile.

2. Sampall: Tha sampall an-asgaidh airson deuchainn.

3. Deuchainnean: Deuchainn spraeadh salainn / Deuchainn tensile / Eddy gnàthach / Deuchainn co-dhèanamh ceimigeach a rèir iarrtas luchd-ceannach

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Teisteanas

Iarrtas