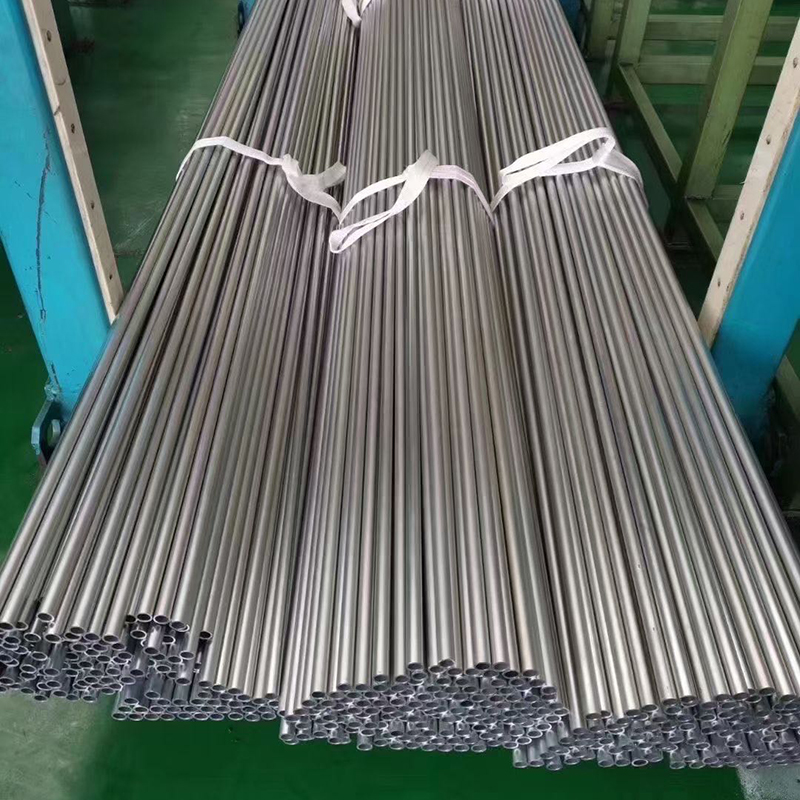

JIS G3445 STKM11A STKM12B STKM13B Tube stàilinn gun fhiosta

Feartan

Ìre stuth:

STKM 11A 12A 12B 12C 13A 13B 13C 14A 14B 14C 15A 15C etc.

Làimhseachadh uachdar:

1.Bared

2.Black Painted (còmhdach varnish)

3.Galvanized

4.Oiled

5.According do luchd-ceannach.

Tha pìoban stàilinn mionaideach JIS G3445 air an cleachdadh sa mhòr-chuid ann am pàirtean innealan càr is mionaideach airson càraichean agus siolandair.cleachdadh cuideam, agus cuideachd airson loidhnichean smùide, uisge, gas a ghiùlan.

Co-dhèanamh ceimigeach

| Ìre | Ainmeachadh | Aonad (%) | ||||||

| C | Si | Mn | P | S | Nb no V | |||

| Ìre 11 | A | STKM 11A | 0.12 air a char as àirde | 0.35 aig a’ char as àirde. | 0.60 aig a’ char as àirde. | 0.040 air a char as àirde | 0.040 air a char as àirde | - |

| Ìre 12 | A | STKM 12A | 0.20 aig a’ char as àirde. | 0.35 aig a’ char as àirde. | 0.6 aig a’ char as àirde. | 0.04 aig a’ char as àirde | 0.04 aig a’ char as àirde | |

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Ìre 13 | A | STKM 13A | 0.25 aig a’ char as àirde. | 0.35 aig a’ char as àirde. | 0.30~0.90 | 0.040 air a char as àirde | 0.040 air a char as àirde | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Ìre 14 | A | STKM 14A | 0.30 aig a’ char as àirde. | 0.35 aig a’ char as àirde. | 0.30 ~ 1.00 | 0.040 air a char as àirde | 0.040 air a char as àirde | - |

| B | STKM 14B | |||||||

| C | STKM 14C | |||||||

| Ìre 15 | A | STKM 15A | 0.25~0.35 | 0.35 aig a’ char as àirde. | 0.30 ~ 1.00 | 0.040 air a char as àirde | 0.040 air a char as àirde | - |

| C | STKM 15C | |||||||

| Ìre 16 | A | STKM 16A | 0.35~0.45 | 0.40 aig a’ char as àirde | 0.40 ~ 1.00 | 0.040 air a char as àirde | 0.040 air a char as àirde | - |

| C | STKM 16C | |||||||

| Ìre 17 | A | STKM 17A | 0.45~0.55 | 0.40 aig a’ char as àirde | 0.40 ~ 1.00 | 0.040 air a char as àirde | 0.040 air a char as àirde | - |

| C | STKM 17C | |||||||

| Ìre 18 | A | STKM 18A | 0.18 aig a’ char as àirde | 0.55 aig a’ char as àirde. | 1.50 aig a’ char as àirde. | 0.040 air a char as àirde | 0.040 air a char as àirde | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Ìre 19 | A | STKM 19A | 0.25 aig a’ char as àirde. | 0.55 aig a’ char as àirde. | 1.50 aig a’ char as àirde. | 0.040 air a char as àirde | 0.040 air a char as àirde | - |

| C | STKM 19C | |||||||

| Ìre 20 | A | STKM 20A | 0.25 aig a’ char as àirde. | 0.55 aig a’ char as àirde. | 1.60 aig a’ char as àirde. | 0.040 air a char as àirde | 0.040 air a char as àirde | 0.15 aig a’ char as àirde |

Feartan meacanaigeach

| Ìre stàilinn | Neart toraidh (Mpa) | Neart tensile (Mpa) | Leudachadh (%) | |

| Ainm | Chan eil. | ReH (mion) | Rm(mion) | A(mion) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 | 20 |

| STKM13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

Fulangas

| MÒR | Fulangas ceadaichte | Fulangas sònraichte | ||

| OD | WT | OD | WT | |

| 4mm-20mm | ±0.25mm | <3mm±0.3mm;

≥3mm ±10%

| ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.25mm | ±0.08mm | ±0.08mm | |

| 31mm-40mm | ±0.25mm | ±0.10mm | ±0.08mm | |

| 41mm-49mm | ±0.25mm | ±0.15mm | ±0.15mm | |

| 50mm-80mm | ±0.5% | ±0.20mm | ±0.20mm | |

| 81mm-120mm | ±0.5% | ±0.30mm | ±0.30mm | |

Suidheachadh lìbhrigidh

| Ainmeachadh | samhladh | Tuairisgeul |

| Crìochnaichte fuar (cruaidh) | BK(+C) | Cha bhith pìoban a’ faighinn làimhseachadh teas às deidh an fuachd mu dheireadh a chruthachadh agus, mar sin, tha iad gu math àrd an aghaidh deformachadh |

| Crìochnaichte fuar (bog) | BKW | Tha an làimhseachadh teas mu dheireadh air a leantainn le dealbh fuar le beagan deformachadh.Tha tuilleadh giollachd iomchaidh a’ ceadachadh ìre sònraichte de fhuarachadh (me lùbadh, leudachadh) |

| (+LC) | ||

| Crìochnaichte fuar agus faochadh cuideam | BKS(+SR) | Tha làimhseachadh teas air a chuir an sàs às deidh a ’phròiseas cruthachadh fuachd mu dheireadh.Le ùmhlachd do chumhachan giullachd iomchaidh, tha an àrdachadh anns na cuideaman a tha air fhàgail a ’comasachadh an dà chuid cruthachadh agus innealachadh gu ìre. |

| Annealed | GBK(+A) | Tha am pròiseas cruthachaidh fuachd mu dheireadh air a leantainn le bhith a’ annealing ann an àile fo smachd. |

| Normalaichte | NBK(+N) | Tha am pròiseas cruthachaidh fuar mu dheireadh air a leantainn le bhith a’ cur anail os cionn na h-ìre cruth-atharrachaidh àrd ann an àile fo smachd. |

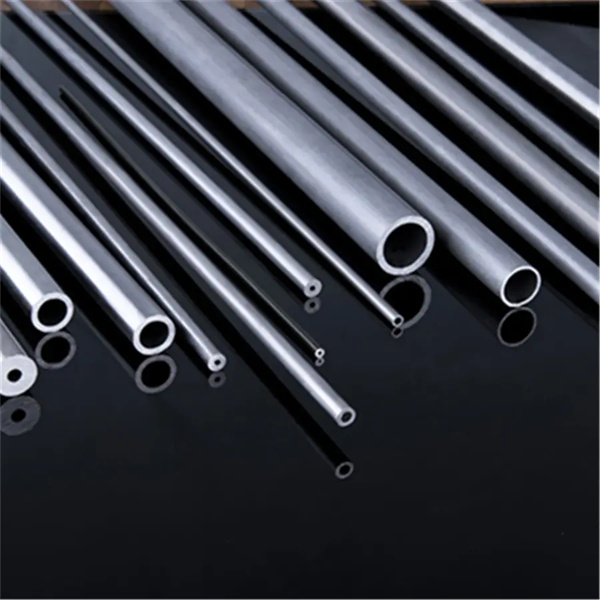

| Tiùban stàilinn àrd-chruinneas ann an stoc | ||||||||||

| OD | Tighead(mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Nota: Dh'fhaodadh sinn meudan eile a thoirt gu buil mar na riatanasan agad.Làimhseachadh uachdar: Bright, Galvanized, Phosphate etc. | ||||||||||

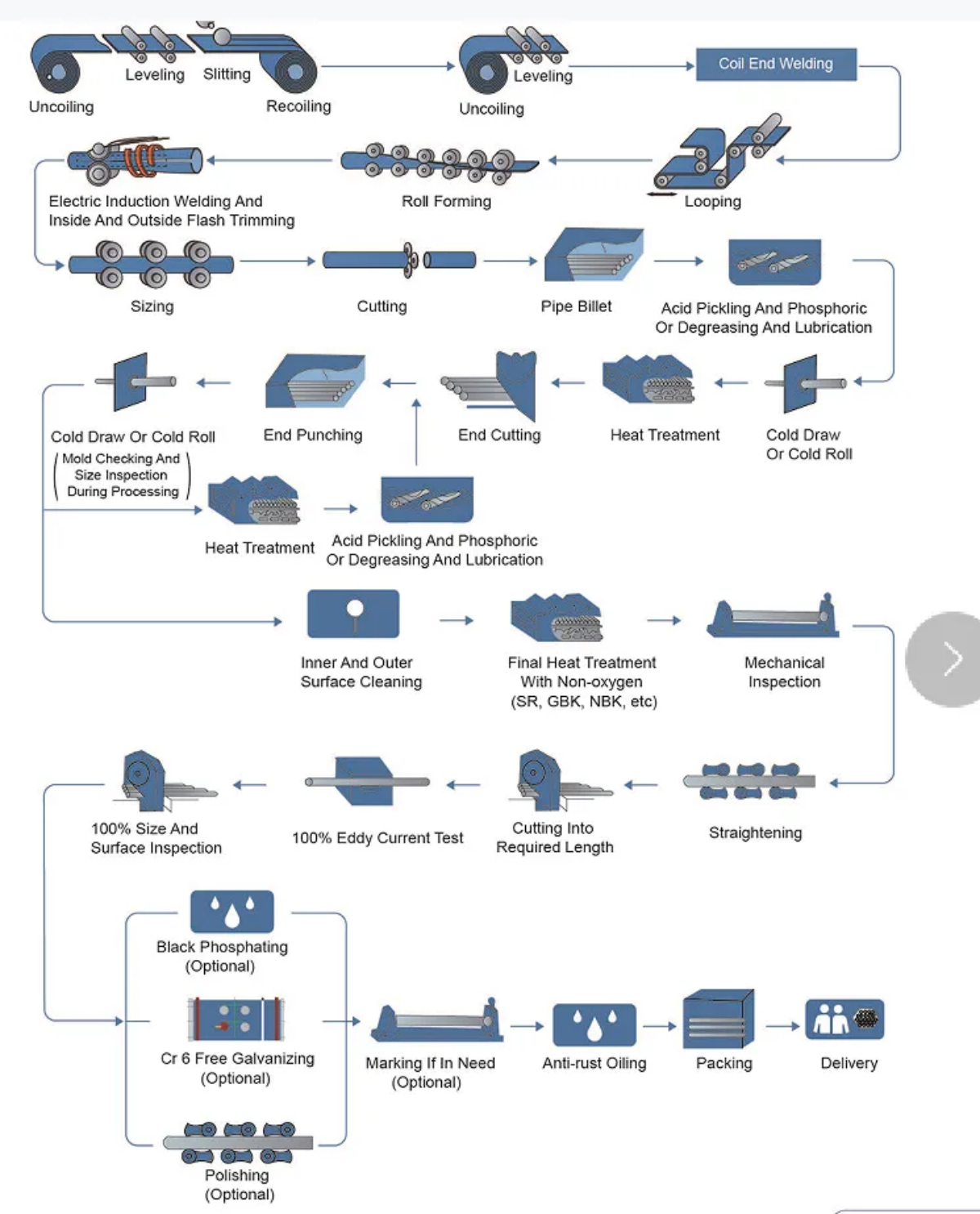

Pròiseas Dèanamh

Buannachdan

Neartaich sgrùdadh thoraidhean anns gach ìre toraidh, uidheamaichte le uidheamachd deuchainn iomlan: deuchainn gnàthach eddy neo-sgriosail, inneal deuchainn an aghaidh cuideam àrd, inneal deuchainn tensile meacanaigeach uile-choitcheann, inneal deuchainn lasraichean lùbadh rèidh, anailisiche glainead, anailisiche eileamaid meatailt, msaa. Coinnich ri feartan meacanaigeach thoraidhean, deuchainn coileanadh pròiseas, thoir seachad gealltanas cumhachdach airson toraidhean le teisteanas.

Dearbhadh càileachd

1. Teann a rèir Inbhe JIS G3445 no inbhean eile.

2. Sampall: Tha sampall an-asgaidh airson deuchainn.

3. Deuchainnean: Deuchainn spraeadh salainn / Deuchainn tensile / Eddy gnàthach / Deuchainn co-dhèanamh ceimigeach a rèir iarrtas luchd-ceannach

4.Certificate: IATF16949, ISO9001, SGS etc.

5.EN 10204 3.1 Teisteanas